Introduction : In the realm of construction and industrial applications, the term ‘wire mesh’ resonates with undeniable significance. Welded wire mesh, with its impressive versatility and strength, stands as a cornerstone in the edifice of modern construction and design. For those seeking superior structural support and security, understanding the intricacies of welded wire mesh is paramount. What is Wire Mesh? Wire mesh is an array of intersecting wires welded or woven at regular intervals, forming a barrier that can be used in countless ways. Typically crafted from materials like steel, stainless steel, or aluminum, wire mesh’s applications stretch from

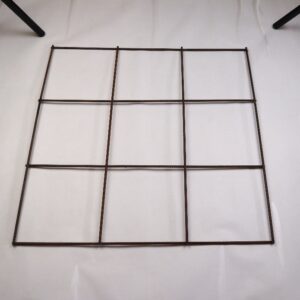

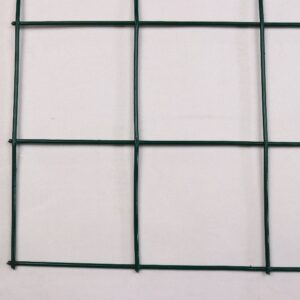

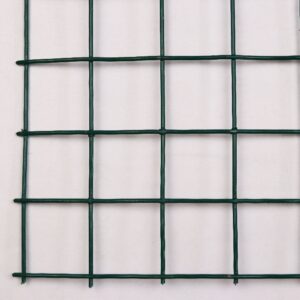

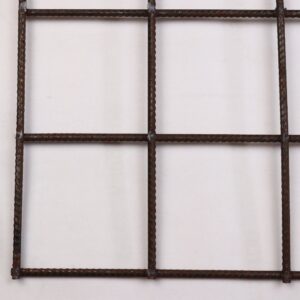

the bedrock of buildings to the summit of sculptures. The Making of Welded Wire Mesh: The journey from raw metal to robust mesh is one of precision engineering. Welded wire mesh is crafted through a process that involves drawing, straightening, and cutting wires before meticulously welding them together at each intersection. This fusion creates a uniform sheet of mesh that can be tailored to any specification.

Key Features and Advantages of Welded Wire Mesh: With an array of beneficial attributes, welded wire mesh is the go-to material for those who prioritize durability. It resists wear and tear, stands up to environmental challenges, and remains steadfast in the face of physical strain. Its adaptability to different environments and ease of

installation make it a cost-effective solution for a variety of needs. Applications of Welded Wire Mesh: From reinforcing concrete in skyscrapers to protecting crops in agricultural settings, welded wire mesh is omnipresent. Its presence in industrial setups as guards or shelves underscores its utility and the trust placed in its strength and stability. Choosing the Right Welded Wire Mesh: Selecting the perfect mesh requires a keen eye for detail. Factors like the environment of application, load-bearing requirements, and specific dimensions must guide the choice. Corrosion resistance and tensile strength also play critical roles in determining the appropriate mesh.

Sustainability and Welded Wire Mesh: The production of wire mesh, with an eye on sustainability, ensures that the environmental impact is kept to a minimum. The ability to recycle and repurpose wire mesh contributes to its status as an eco-friendly option. Installation Tips and Best Practices: Proper installation is key to maximizing the benefits of welded wire mesh. Employing correct techniques and regular maintenance can vastly extend the life span of wire mesh installations. Why Choose Our Welded Wire Mesh: Aim Industries commitment to quality ensures that each sheet of welded wire mesh meets the highest standards. With options for customization and dedicated customer support, we provide solutions that cater to the unique needs of each project. Welded wire mesh is more than just a material; it’s a testament to the ingenuity of modern engineering. As you embark on your next project, consider the unmatched quality and versatility of our welded wire mesh. Visit our website for an in-depth look at our products, and don’t hesitate to reach out for personalized advice and quotations to meet your project’s specifications.